Don't have an account? Join for free

For advertising on

Interest to become a seller? Get info

Equity, Diversity and Inclusion best recruitment practices

Waterloo University has a Western Canadian Team to assist with any co-op student requirements.![]() University of Waterloo in Waterloo

University of Waterloo in Waterloo

Fostering Equity, Diversity, and Inclusion in Recruitment: Insights for the Oil Industry in Western Canada We are committed to guiding businesses in the Western Canadian oil industry towards adopting best practices in Equity, Diversity, and Inclusion (EDI) for recruiting future-ready talent. The emerging workforce, particularly Generation Z, is increasingly prioritizing EDI and anti-racism in their employment choices. Understanding the Emerging Workforce Generation Z, born between 1996-2014, represents the most diverse group of employees to enter the workforce. This generation, akin to many of our co-op students, places significant importance on social awareness and workplace inclusivity. Implementing EDI Best Practices To attract, engage, and retain this talent, it's crucial for organizations to prioritize EDI. Research from Waterloo’s Work-Learn Institute suggests several effective practices: Unconscious Bias Training: Equip your team with the knowledge to recognize and address unconscious biases. Blind Recruitment Practices: Implement recruitment strategies that focus on skills and qualifications, minimizing bias. Inclusive Policies: Adopt culturally sensitive policies, such as gender-neutral language and recognition of lived gender identities. Broadening Criteria: Look beyond traditional Canadian experience and credential requirements to embrace a wider talent pool. The Impact of Social Awareness on Recruitment Gen Z’s Priorities: A Monster survey revealed that 83% of Gen Z candidates consider a company’s commitment to inclusion crucial in their employer selection. Social Movements Influence: The resurgence of movements like Black Lives Matter and a growing awareness of systemic racism emphasize the need for robust EDI practices. By embracing these EDI best practices, the oil industry in Western Canada can not only attract but also nurture a workforce that is diverse, inclusive, and future-ready. The University of Waterloo’s Co-operative Education program is dedicated to supporting these initiatives, fostering an environment where every talent is valued and nurtured.

Service

Made to Order

Service

New

ISO

Air Freight

![]() InWaTec Combined in Vechta

InWaTec Combined in Vechta

Revitalizing Wells with Precision: InWaTec Combined’s E-line Re-perforating Services In the lifecycle of an oil or gas well, the need to enhance production or manage reservoir depletion often leads to re-perforating—a strategic intervention aimed at revitalizing well performance. InWaTec Combined's E-line Re-perforating Services leverage the proven efficacy of wireline technology to refine and optimize this crucial process. Wireline, or electric line, has been the traditional mode for deploying perforating guns due to its substantial benefits. The real-time depth control ensures that each perforation is placed with surgical precision, while the selectivity afforded by wireline allows for targeted interventions, focusing on zones with the greatest potential for increased production. Moreover, the reduced logistics of wireline operations, as opposed to tubing deployment, offer a streamlined, cost-effective approach to well servicing. Historically, wireline perforating guns were differentiated based on their use—either as casing guns for pre-completion perforation or through-tubing guns for post-completion jobs. In today's industry, however, this distinction has been transcended. InWaTec Combined has embraced the versatility of wireline to deliver any engineered perforating system, regardless of the well's stage of life, alongside an extensive array of explosive devices. Our E-line Re-perforating Services are not merely about revisiting existing perforations. They represent a strategic re-evaluation and reconfiguration of the well's production strategy. Whether it's addressing areas of the reservoir that were initially bypassed, bypassing damaged perforations, or creating new pathways in depleted zones, our re-perforating services are tailored to meet the unique demands of each well. At InWaTec Combined, we understand that re-perforating is an opportunity to enhance well productivity significantly. Our expert teams, equipped with advanced diagnostic tools, evaluate the well's current status to identify the most promising zones for re-perforation. With this data, we employ the latest in shaped-charge technology and explosive devices, ensuring that new perforations deliver the maximum flow and recovery possible. Choosing InWaTec Combined's E-line Re-perforating Services means entrusting your well's performance to a company that values precision, efficiency, and innovation. Our commitment to excellence ensures that your re-perforating interventions are executed with the highest level of expertise, from planning to execution. Partner with us to revitalize your wells. With InWaTec Combined's E-line Re-perforating Services, you can expect to turn potential into production, optimizing your well's output and extending its productive life. Let us help you unlock the hidden value in your wells, one precise perforation at a time.

Service

In Stock

Service

New

API

Land Freight

![]() Midastream Supply Company in Airdrie

Midastream Supply Company in Airdrie

The T, T-CL, C-SRL-CL and CXS Tubing Hangers are all single completion, mandrel-type hangers for use in either the C Tubing Spool or the CD-2 Tubing Spool. T Tubing Hanger The T Tubing Hanger withstands stress of high pressure, corrosive/erosive elements associated with well flow. Its flexible neck maintains the metal seal despite thermal or pressure cycling. T-CL Tubing Hanger The T-CL Tubing Hanger withstands stress of high pressure, corrosive/erosive elements associated with well flow. A control line exit block is available in either a bull plug style or block needle valve style. C-SRL-CL Tubing Hanger The C-SRL-CL Tubing Hanger incorporates a pressure energized SRL neck seal which accommodates vertical movement in the tubing hanger during BOP testing. A control line exit block is available in either a bull plug style or block needle valve style. The C-SRL-CL hanger should be used in 7-1/16” 10,000 psi Type C Tubing Spools. CXS Tubing Hanger The CXS Tubing Hanger includes two neck seals which may be used to isolate one control line.

Buy

Made to Order

Product

New

API

Air Freight

![]() Hoca Oil Tools in Zwartemeer

Hoca Oil Tools in Zwartemeer

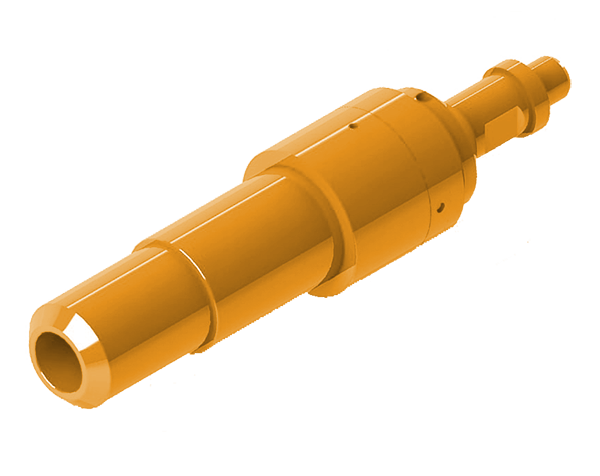

Secure and Optimize Your Downhole Operations with HOCA Oil Tools' Check Set Tool In the intricate world of oil and gas exploration and extraction, securing and optimizing downhole components are pivotal for operational success and safety. HOCA Oil Tools, a leader in downhole slick line tool solutions, presents the Check Set Tool, an innovative product designed to ensure the correct setting and functionality of downhole locks and plugs. This specialized tool is an essential part of maintaining well integrity and efficiency, demonstrating our commitment to providing high-quality, reliable downhole solutions. HOCA’s Check Set Tool: Ensuring Downhole Safety and Efficiency The Check Set Tool by HOCA Oil Tools is engineered with precision, built to verify the accurate setting of lock mandrels and other downhole locking devices. Crafted from robust materials suited for the harsh downhole environment, this tool is designed for reliability and durability, ensuring that your downhole operations run smoothly and securely. Elevate Your Downhole Tool Setting with HOCA Oil Tools At HOCA Oil Tools, we understand the challenges and risks associated with downhole operations. Our Check Set Tool is a reflection of our dedication to innovation, quality, and customer service, offering a solution that addresses the critical need for secure and efficient downhole tool settings. Integrating the HOCA Check Set Tool into your downhole operations not only enhances operational security and efficiency but also demonstrates a commitment to the highest standards of well integrity and safety. Our experienced team is dedicated to supporting your operational success, providing tools and solutions that meet the demanding conditions of the oil and gas industry. Invest in the HOCA Check Set Tool and experience the confidence and efficiency that come with knowing your downhole components are correctly set and secured. Choose HOCA Oil Tools for all your downhole needs and join the ranks of satisfied customers who trust our products to keep their operations running smoothly and safely.

Buy

In Stock

Product & Service

New

API

Air Freight

![]() Midastream Supply Company in Airdrie

Midastream Supply Company in Airdrie

A tricone bit is a mechanical drill bit located in the bottom hole assembly. The bit cuts away the surface of the rock being drilled through rotation and mechanical friction caused by the teeth of the bit. A tricone bit is a drill bit with a head that is divided into three main parts. Tricone bits are designed to take the energy of the rotating drill string and the supply of mud and to apply this force to deepen the well. The tricone bit consists of three rotating cones working inside each other and each with its own row of cutting teeth.

Buy

Made to Order

Distributor

New

API

Sea Freight

![]() Sivam S.p.A. in Spoltore

Sivam S.p.A. in Spoltore

Introducing Sivam's Sand Trap: The Ultimate Solution for Sand Separation in the Oil and Gas Industry! Our innovative sand separation technology is designed to improve the efficiency and performance of oil and gas operations by effectively removing sand from production streams. Sivam's Sand Trap is a game-changer in the oil and gas industry. Our cutting-edge technology works by changing the flow parameters, reducing the flow velocities to the point where the sand drops out while gas and fluids are carried through. This process involves no bags, filters, screens, and virtually no pressure drop, making it the most efficient and cost-effective solution for sand separation on the market. Our Sand Trap is designed with durability and reliability in mind. It can handle high flow rates and is built to withstand harsh conditions, ensuring optimal performance even in the most challenging environments. And with no moving parts, it requires minimal maintenance, reducing downtime and operating costs. One of the key benefits of Sivam's Sand Trap is its versatility. It can be used in a variety of applications, from primary production to enhanced recovery, and can be customized to meet the specific needs of your operation. And with its compact design, it can be easily installed and integrated into your existing system. At Sivam, we pride ourselves on providing exceptional customer service and support. Our team of experts is always available to assist you with any questions or concerns you may have, ensuring that you get the most out of your Sand Trap. Overall, Sivam's Sand Trap is the ultimate solution for sand separation in the oil and gas industry. With its cutting-edge technology, versatility, and efficiency, you can trust that our Sand Trap will exceed your expectations. Contact us today to learn more about how Sivam's Sand Trap can benefit your business.

Rental

In Stock

Product & Service

New

ISO

Land Freight

![]() University of Waterloo in Waterloo

University of Waterloo in Waterloo

Navigating U.S. Visa Processes for Hiring Waterloo Co-op Students in the Oil Industry" We are committed to facilitating a smooth transition for our co-op students employed in the oil industry in the United States. For non-Canadian employers, it's crucial to understand the U.S. J-1 visa process to ensure a seamless hiring experience. Key Steps in the U.S. J-1 Visa Process Communicate Essential Details: Inform your co-op student about the start and end dates, compensation, relocation expenses, cultural onboarding resources, and local transit information. Visa Sponsorship and Fees: Discuss and confirm the visa sponsor choice with your co-op student and be aware of the administrative fee for the visa process. Timely Visa Application: Start the J-1 visa process as soon as possible after matching with a student. This process can take several weeks, especially if the student is not a Canadian citizen. Employer’s Role: Choose a Sponsor: Determine if your organization will use a sponsor. Preferred sponsors include Cultural Vistas and Intrax. Prepare Application Documents: Follow the guidelines provided by your sponsor for J-1 application documents. Pay Fees: Cover the application and processing fees. Obtain DS-2019 Form: The sponsor issues this form, which is necessary for Canadian students to obtain their J-1 visa. Additional Steps for Non-North American Students: Students from countries other than the U.S. and Canada must also undergo an interview at a U.S. Consulate, adding 2-6 weeks to the process. Support from the University of Waterloo Our International Employment Services team (ceeusaies@uwaterloo.ca) assists in coordinating with preferred sponsors. The Co-operative and Experiential Education department provides work term readiness training, covering taxes, social security numbers, health insurance, risk management, and more. For Employers Outside Canada and the U.S. Contact our International Employment Specialist for guidance on international co-op employment. Navigating the U.S. J-1 visa process is a critical aspect of hiring University of Waterloo co-op students for roles in the United States. By understanding and adhering to these guidelines, employers in the oil industry can ensure a smooth and compliant hiring process, benefiting from the diverse talents of our students.

Service

Made to Order

Service

New

ISO

Air Freight

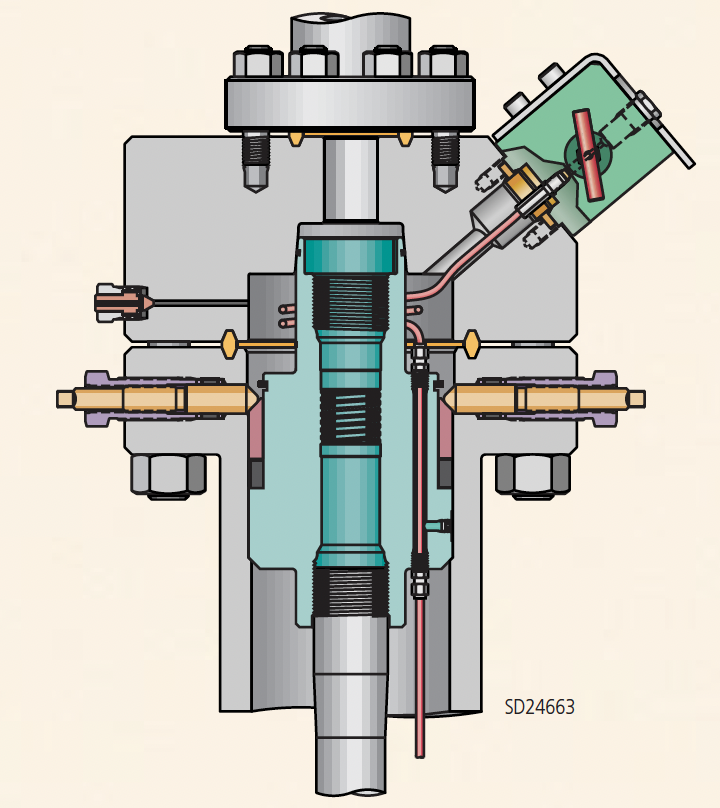

Surface Controlled Subsurface Safety Valve FRN 6-5/8 inch

WR-SCSSSV FRN![]() Midastream Supply Company in Airdrie

Midastream Supply Company in Airdrie

The FRN wireline-retrievable flapper valve, which is normally closed, is held open by hydraulic control pressure from the surface. The valve operates on a hydraulic-piston principle. To open, tubing pressure slightly higher than the well pressure below the closed flapper is applied. Once well pressure is equalized across the closed flapper, hydraulic pressure is applied to the piston, which pushes the flapper open. The flapper hinge assembly is designed so the force on the piston is not applied directly on the hinge pin. Upon loss of hydraulic pressure in the control line, the valve's large spring serves to lift the hydrostatic head of the control fluid. The flapper spring is designed to close the valve when the piston moves up past the flapper. Opening Prong Nose Seal The FRN valve uses the valve housing as the downstop for the opening prong. This metal-to-metal (MTM) interface is designed to prevent flow from passing between the valve housing and opening prong. The MTM interface isolates the flapper and seat from fluid flow while the valve is open. This design creates an MTM interface with the full force exerted by the hydraulic piston, minus the spring compression force, holding the two metal faces in contact. Radius of Curvature at Flow Entrance Halliburton conducted a study with various curvatures on the entrance to the valve. The study tested abrasive fluids flowing through different test subs and examined the resulting wear patterns. As a result, an optimum radius of curvature was determined and implemented on the valve housings of all wireline retrievable safety valves. Applications » New completions » Deep set » High pressure Features » High-strength rod-piston actuation » Non-equalizing flapper closure » Solid construction flapper made from bar stock » Spherical radius seat on flapper improves seal reliability » Sealing and seating surfaces are out of flow path of well production when valve is in open position » Designed for easy field servicing *information referenced from supplier catalog.

Buy

Made to Order

Product

New

API

Air Freight