Don't have an account? Join for free

For advertising on

Interest to become a seller? Get info

Workover

Slickline

Slickline Basic Tools

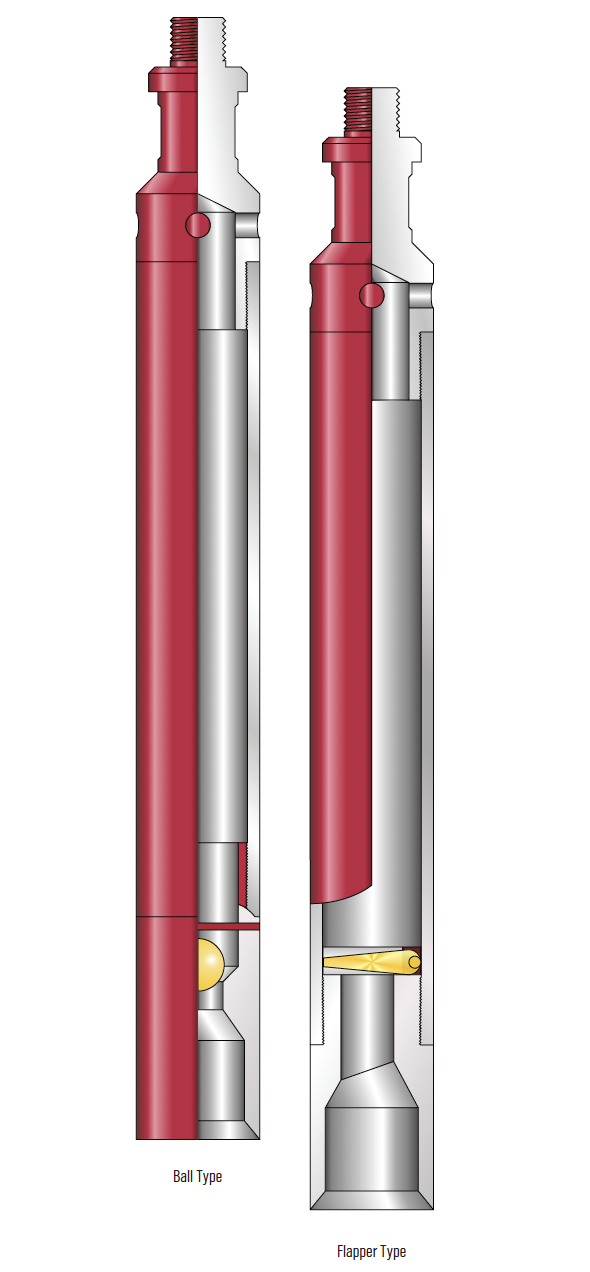

The Drive Down Bailer is used to collect samples or remove debris from the wellbore. The Bailer is jarred into the sample or debris forcing material into the cylinder, which is retained by a ball or flapper type non-return seat. The bailer is then jarred upwards and retrieved. Applications • Recovery of in-fill samples from wellbore or sump • Removal of compacted debris or sand from flow control devices

Buy

Currently in Use

Distributor

New

API

Land Freight

HOCA Oil Tools B.V.'s Expertise in Slickline Rope Sockets In the dynamic world of oil and gas extraction, precision and reliability are paramount. At HOCA Oil Tools B.V., we take pride in our extensive expertise in slickline operations, particularly our specialized rope sockets designed for varied downhole conditions. Our product range includes Type ‘AO’, ‘AD’, ‘AS’, ‘BO’, ‘BD’, ‘BS’, ‘CO’, ‘CD’, ‘CS’,‘CGO’, ‘D’, ‘DD’, ‘DS’, ‘GO’, ‘RC’, ‘SA’, ‘HO’, and ‘HD’ rope sockets, each tailored for specific wireline tasks and environmental conditions. Our rope sockets are crafted from high-quality alloy materials, ensuring durability and optimal performance. They cater to a wide range of wire sizes and types, accommodating single-strand, multi-strand, and encapsulated lines. With features like spring disc supports, releasing slips, and heavy-duty clamps, our rope sockets ensure secure connections and safe operations under intense downhole pressures. The main features of some of the various rope sockets offered by HOCA Oil Tools B.V. are as follows: Type ‘CGO’ Rope Socket: Designed for use with small stranded lines up to 1/4” diameter, this rope socket has an additional swivel bottom, making it similar in design to the Type ‘CO’ but with enhanced functionality for specific applications requiring rotation. Type ‘D’ Dummy Rope Socket: Available with threaded or QLS Connections, this tool can be attached to other types of tools with a pin connection for various wireline applications, offering great versatility and adaptability in operational setups. Type ‘GO’ Rope Socket: Engineered specifically for single conductor cable heads, providing secure and reliable connections for specialized wireline operations. Type ‘RC’ Rope Socket: This assembly is tailored for encapsulated line applications, offering enhanced protection and durability for operations involving encapsulated cables. Type ‘SA’ Rope Socket: Designed for swabbing applications with Babbitt fill, this rope socket is tailored for operations requiring the retrieval of fluids from wells, ensuring efficient and reliable performance. Type ‘HO’ and ‘HD’ Heavy Duty Rope Socket: These are intended for heavy-duty wireline work and feature a unique design that traps the wire, held in place with socket screws, suitable for more demanding operations and environments. Each type of rope socket has unique features tailored to different wireline operations, ensuring that HOCA Oil Tools B.V. can provide a suitable solution for a wide range of downhole conditions and requirements. HOCA Oil Tools B.V. stands at the forefront of slickline technology, offering solutions that ensure safety, efficiency, and reliability. Our commitment to innovation and quality has established us as a trusted partner in the oil and gas industry worldwide.

Buy

In Stock

Product & Service

New

API

Air Freight

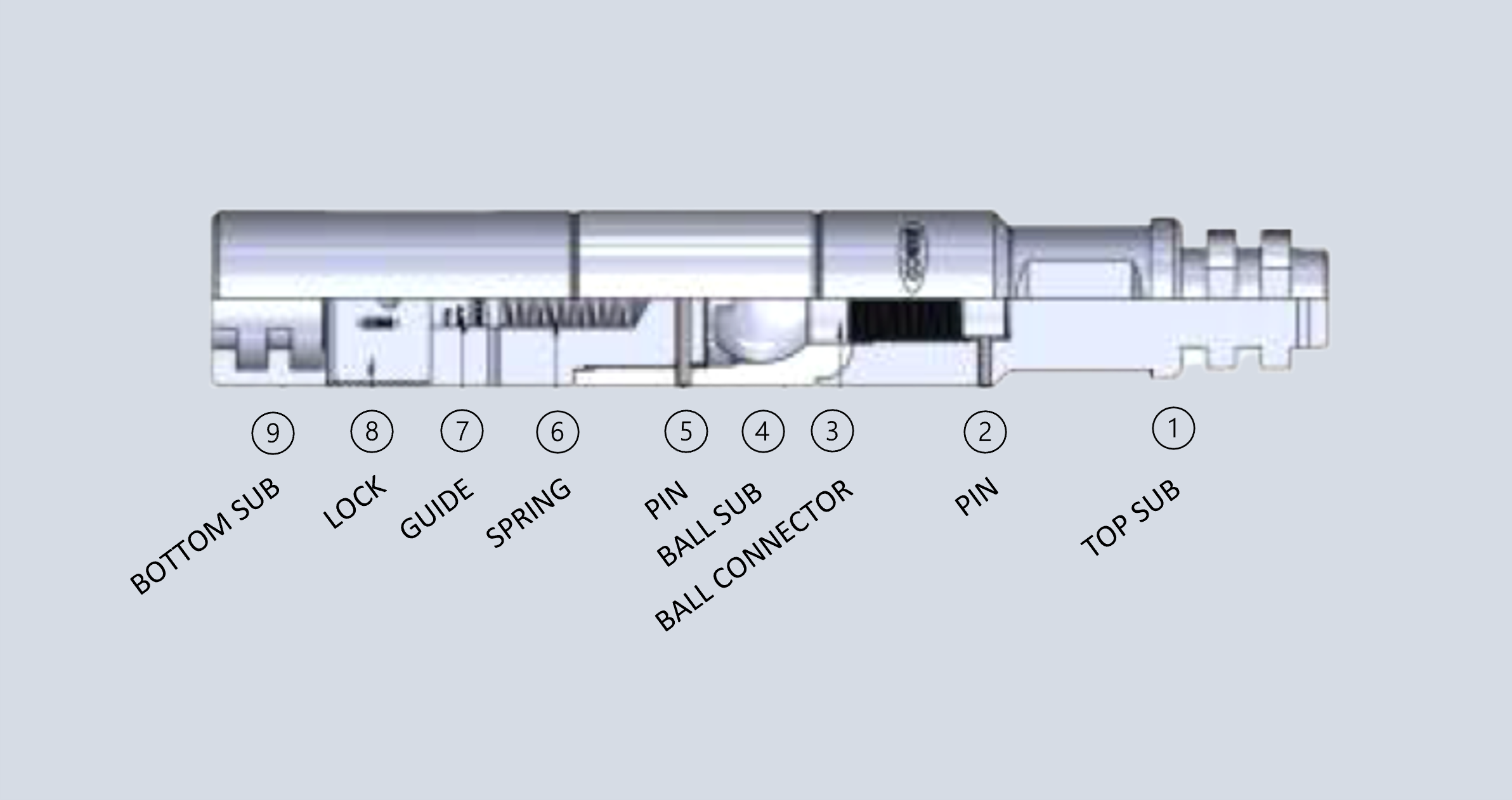

Unlocking Efficiency in Downhole Operations: HOCA Oil Tools B.V.'s Advanced Slickline Swivel Joints In the dynamic landscape of downhole operations, the role of slickline swivel joints becomes pivotal in ensuring seamless, efficient, and safe wireline operations. HOCA Oil Tools B.V., a renowned name in the oil and gas industry, stands at the forefront of delivering cutting-edge slickline solutions. Our array of slickline swivel joints is designed to meet and exceed the operational demands and challenges faced by our clients. Pioneering Slickline Swivel Joints: HOCA Oil Tools B.V. offers an extensive range of slickline swivel joints, including the Type ‘HO’ and ‘HD’ swivel joints, engineered to minimize wireline twisting during downhole operations. This not only enhances safety but also improves operational efficiency by reducing the risk of wireline entanglement and breakage. Key Benefits of Our Slickline Swivel Joints: Reduced Wireline Twisting: Our swivel joints significantly reduce the twisting of wireline, thus minimizing the risk of operational downtime and wire breakage. Enhanced Operational Safety: By preventing wireline kinks and twists, our swivel joints contribute to safer downhole operations, protecting both personnel and equipment. Increased Efficiency: Smooth wireline operations ensure quicker job completion and reduced non-productive time. Durability and Reliability: Made from high-grade materials, our swivel joints withstand harsh downhole conditions, ensuring long service life and reliability. Versatility: Available in various sizes and configurations, our swivel joints cater to a wide range of downhole requirements and wireline types. Ease of Integration: Designed for easy integration into existing tool strings, our swivel joints facilitate seamless operations without the need for extensive modifications. Main Features of HOCA's Slickline Swivel Joints: Type ‘HO’ Swivel Joint: Designed to minimize wireline twisting, available in sizes from 1” to 2 1/2", with threaded connections for easy installation. These swivel joints feature top sub, pin, ball connector, ball sub, and bottom sub components, ensuring robust performance and ease of maintenance. Type ‘HD’ Swivel Joint: Similar to the Type ‘HO’ but designed for even more demanding environments, with ‘QLS’ - ‘RQLD’ connections, providing additional strength and durability. These swivel joints are also available in sizes from 1 1/2” to 2 1/2", tailored for heavy-duty operations. At HOCA Oil Tools B.V., we understand the complexities of downhole operations. Our slickline swivel joints are a testament to our commitment to innovation, safety, and efficiency. Embrace the future of wireline operations with HOCA, where performance meets reliability. Contact us today to learn more about how our slickline solutions can optimize your operations.

Buy

In Stock

Product & Service

New

API

Air Freight

Elevating Downhole Precision: HOCA Oil Tools B.V.'s Slickline Stem Solutions In the intricate arena of oil and gas extraction, downhole operations necessitate tools that promise not only precision but also unwavering reliability. HOCA Oil Tools B.V. takes pride in offering a sophisticated range of slickline stems that cater to a myriad of operational needs, ensuring unmatched performance and safety. Our expertise in crafting these essential tools is evident from the wide array of slickline stems available, designed to enhance the efficiency and safety of wireline operations. Benefits of Using HOCA's Slickline Stems: Enhanced Downhole Control: Our stems provide the necessary weight to ensure smooth and controlled movements of the tool string within the wellbore, enhancing operational precision. Versatility for Various Applications: From standard solid bars to specialized options like lead or tungsten filled, our range caters to different well conditions and requirements. Optimized Performance: The added weight helps counteract wellbore pressure, improving the impact and effectiveness of downhole tools, particularly in jarring operations. Increased Safety: Proper use of slickline stems reduces the risk of wireline snapping and other operational hazards, ensuring a safer environment for field personnel. Durability in Harsh Conditions: Manufactured with high-quality materials, our stems are designed to withstand the demanding conditions of downhole environments. Customization Options: Available in various sizes and materials, our stems can be tailored to meet the specific needs of each operation, ensuring maximum efficiency and effectiveness. Main Features of HOCA's Slickline Stems: Type ‘A’ Stem (Weight Bar): Offers solid bar configurations ideal for standard operations, providing necessary weight to the tool string with threaded connections for easy integration. Type ‘BO’ Lead Filled Stem: Incorporates lead within the stem to add substantial weight, ideal for deeper or more challenging well conditions, ensuring better control and impact. Type ‘EO’ Roller Stem: Features external rollers to minimize friction and wear during operations, enhancing the stem's longevity and performance in deviated wells. Type ‘ED’ Tungsten Filled Stem: Utilizes tungsten to provide maximum weight in a minimal space, perfect for high-pressure wells where additional downforce is required. Customization and Variety: Our stems are available in various lengths, diameters, and thread connections, ensuring compatibility with different tool strings and operational needs. HOCA Oil Tools B.V.'s commitment to quality and innovation is reflected in our slickline stem offerings. By providing a comprehensive range of sizes, materials, and types, we ensure that our clients have access to the tools necessary for their unique downhole challenges. Trust HOCA for your downhole tool needs, where precision meets durability.

Buy

In Stock

Product & Service

New

API

Air Freight

Maximizing Downhole Efficacy with HOCA Oil Tools B.V.'s Slickline Jars In the ever-evolving landscape of oil and gas exploration and production, the precision and reliability of downhole operations are paramount. At HOCA Oil Tools B.V., we pride ourselves on our extensive expertise and innovative solutions in the field of slickline technology, particularly our diverse array of slickline jars designed to address a wide range of downhole challenges. Unparalleled Benefits of HOCA's Slickline Jars: Enhanced Operational Efficiency: Our jars significantly reduce non-productive time by enabling more effective and quicker responses to downhole sticking issues. Improved Downhole Dynamics: With the capability to deliver upward and downward jarring forces, our slickline jars optimize the impact on the obstruction, ensuring successful resolution of downhole incidents. Versatility Across Conditions: Designed for a variety of wellbore environments, our jars ensure optimal performance regardless of the downhole conditions. Superior Material and Construction: Crafted from high-grade materials, our jars withstand the extreme pressures and temperatures encountered downhole, ensuring durability and longevity. Customization for Specific Needs: Our extensive range accommodates different sizes and operational requirements, ensuring that every operation has the precise tool needed for the job. Safety and Reliability: Engineered to meet rigorous industry standards, our slickline jars enhance the safety and reliability of wireline operations. Diverse Array of Slickline Jars: Hydraulic Jars: Ideal for controlled, consistent jarring actions in sticky situations, providing the necessary force while minimizing risk to the toolstring and wellbore. Mechanical Jars: Known for their robustness and reliability, suitable for a variety of downhole conditions, offering immediate response to obstructions. Spring-Loaded Jars: Designed for situations requiring fast, sharp impacts, these jars are perfect for dislodging stuck tools or debris. Intensifier Jars: Amplify the impact force, ideal for extreme conditions where additional power is needed for jarring actions. Bi-Directional Jars: Capable of delivering both upward and downward forces, providing versatility and efficiency in clearing obstructions. At HOCA Oil Tools B.V., our commitment to innovation, quality, and customer service is at the core of our business philosophy. Our slickline jars are testament to this commitment, designed not only to meet but exceed the operational demands and challenges faced by our clients in the oil and gas industry. With HOCA Oil Tools B.V., you are choosing a partner dedicated to providing you with the best in slickline technology solutions. Explore our range of slickline jars and discover how we can enhance the efficiency and safety of your downhole operations.

Buy

In Stock

Product & Service

New

API

Air Freight

Maximizing Downhole Dynamics with HOCA Oil Tools B.V.'s Slickline Accelerators In the intricate and demanding world of oil and gas extraction, the precision and effectiveness of downhole operations are paramount. HOCA Oil Tools B.V. is at the forefront of this industry, offering a comprehensive range of slickline accelerators designed to enhance the performance of various jars. Our accelerators are specifically engineered to maintain a constant pull on the jars, ensuring an intensified impact upon release, which is crucial for overcoming downhole challenges. Key Benefits of HOCA’s Slickline Accelerators: Enhanced Jar Performance: Our accelerators ensure a consistent and intensified jarring action, making them essential for effectively addressing downhole obstructions and ensuring operational success. Versatile Application: Compatible with various jars, our accelerators are suitable for a wide range of downhole conditions and operational needs, from routine maintenance to complex interventions. Optimized Impact Delivery: By maintaining a constant pull, our accelerators facilitate the optimal deployment of jars, ensuring that the necessary impact is delivered precisely where it is needed. Increased Efficiency: The improved jarring action provided by our accelerators can significantly reduce the time and effort required to address downhole issues, leading to faster, more efficient operations. Durability and Reliability: Constructed with high-quality materials and engineered to the highest standards, our accelerators are built to withstand the harsh downhole environment, ensuring reliability and longevity. Customization and Compatibility: Available in various sizes and with different connection types, our accelerators can be easily integrated into existing tool strings, providing a tailored solution to meet specific operational requirements. Innovative Features of HOCA’s Slickline Accelerators: Type ‘EO’ and ‘ED’ Accelerators: These models are designed for a range of sizes from 1 1/2” to 2 1/2”, making them adaptable for different operational scales and requirements. Threaded and QLS Connections: Offering flexibility for integration with different tool strings, these connection types ensure that our accelerators can be deployed swiftly and securely in various downhole environments. Optimized Length and Weight: With lengths ranging from 22.66” to 27.95” and weights from 7.0 lbs (3.18 kg) to 24.8 lbs (11.25 kg), our accelerators are engineered for balance and effective force transmission. Robust Construction: Our accelerators are constructed to endure the rigors of downhole operations, ensuring consistent performance and durability over time. At HOCA Oil Tools B.V., we understand the complexities and challenges of downhole operations. Our slickline accelerators are a testament to our commitment to quality, innovation, and customer satisfaction. By incorporating our accelerators into your tool string, you can enhance the efficiency and effectiveness of your downhole operations, ensuring that every intervention is optimized for success. Choose HOCA Oil Tools B.V. for your downhole needs, and experience the difference that quality and innovation can make in your operations

Buy

In Stock

Product & Service

New

API

Air Freight

Knuckle Joint for Wireline Toolstring

Knuckle JointEnhancing Wireline Flexibility with HOCA Oil Tools B.V.'s Advanced Knuckle Joints In the demanding environments of oil and gas extraction, the adaptability and precision of downhole tools are paramount. At HOCA Oil Tools B.V., we specialize in providing state-of-the-art wireline solutions, including our wide range of Knuckle Joints, known for their exceptional flexibility and reliability. Our Knuckle Joints are designed to provide pivotal flexibility in the Wireline Tool String, facilitating angular movement between the tool string and the running or pulling tool, an essential feature for navigating complex downhole geometries. Six Key Benefits of HOCA's Wireline Knuckle Joints: Enhanced Flexibility: Our Knuckle Joints allow for angular movement, enabling the Wireline Tool String to navigate through deviated wellbores efficiently. Improved Tool Placement: By enabling better maneuverability, our Knuckle Joints facilitate precise tool placement, improving the success rates of downhole operations. Increased Operational Range: The added flexibility extends the operational range of wireline tools, allowing for more complex and challenging interventions. Robust Design: Constructed with high-quality materials, our Knuckle Joints withstand harsh downhole environments, ensuring longevity and reliability. Versatile Application: Suitable for a variety of downhole activities, our Knuckle Joints are essential for both standard operations and complex well interventions. Easy Integration: Available with both Threaded and QLS Connections, our Knuckle Joints seamlessly integrate into existing tool strings, enhancing operational efficiency. HOCA's Diverse Array of Wireline Knuckle Joints: Type ‘AO’ Knuckle Joints (Threaded Connection): These are available in sizes from 3/8” to 2 1/2”, designed for easy integration with various tool strings. They offer exceptional flexibility and strength, with sizes accommodating different operational needs, ensuring that tools can navigate wellbore paths effectively. Type ‘AD’ Knuckle Joints (QLS Connection): Catering to advanced operational requirements, these Knuckle Joints provide the same high-level flexibility with quick lock-and-seal connections for faster deployment and retrieval, available in sizes ranging from 1 1/2” to 2 1/2”. Rebco Type ‘AS’ Knuckle Joint (RQLS Connection): An addition to our lineup, offering enhanced swivel action and compatibility with a range of wireline tools, facilitating seamless downhole operations. Each of our Knuckle Joints is engineered with precision, incorporating features such as double fishing necks for increased adaptability and operational safety. The diverse sizes and connection types we offer ensure that there is a HOCA Knuckle Joint suitable for every downhole challenge. By choosing HOCA Oil Tools B.V. for your wireline operational needs, you are selecting a partner dedicated to innovation, quality, and customer service. Our Knuckle Joints represent just one aspect of our commitment to providing the oil and gas industry with tools that meet the highest standards of performance, reliability, and safety. Embrace the flexibility and efficiency of HOCA’s Wireline Knuckle Joints to enhance your downhole operations. Contact us today to learn more about how our tools can transform your well interventions and streamline your operational workflows

Buy

In Stock

Product & Service

New

API

Air Freight